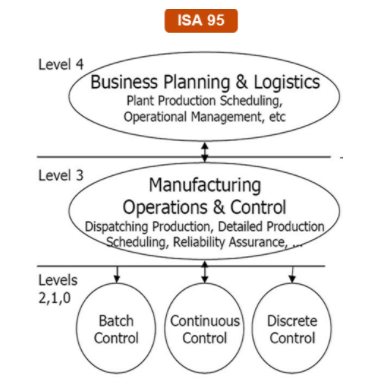

Although currently challenged, due to the advent of the Internet of Things and computing at the edge, Purdue's information architecture model and its adoption by ISA in its S95 standard for integration of manufacturing and business information continues to be valid and is complemented today more than ever in an industrial data platform

The traditional historians of process data have evolved incorporating “modeling” capacity relating the physical units of the process with entities (objects) in the software and also a broad data analysis capacity, becoming Industrial Data Platforms

Beyond all their evolution, the "core" of industrial data platforms continues to be the "industrial process" and depending on the "real time" characteristic in which the information emerges, these platforms continue to focus on data "serialized in time", typically coming from control hardware (PLC's, PCS's) or from HMI / SCADA systems. Traditionally these platforms are known as PIMS or Plant Information Management Systems

For an appropriate vertical integration between the production processes and the business, it is necessary to integrate information from the multiple intervening systems, not only in diversity of sources and formats, but also in multiple generation frequencies, that is, in real and transactional time), currently These new multi-dimensional data platforms suitable for multiple systems to deposit their data to be integrated have begun to take the name of “data lakes” (“Data Lakes”)